A modern approach to interiors

Cutting edge Technology

High-quality edge finishing with speed & consistency

We use an Automatic edge banding machine to enhance efficiency, precision, and high-quality edge finishing with speed, and consistency. This automated edge-finishing process handles glue application, laminating edges, trimming, polishing, and cornering edges. These machines dramatically reduce the production time and increases high precision & quality.

Advantages of Automatic Edge Banding

- Significantly increase production speed

- Efficient & consistent edge finishing

- Improved product quality

- Versatility in handling various edge materials

- Enhanced safety through auto edge banding process.

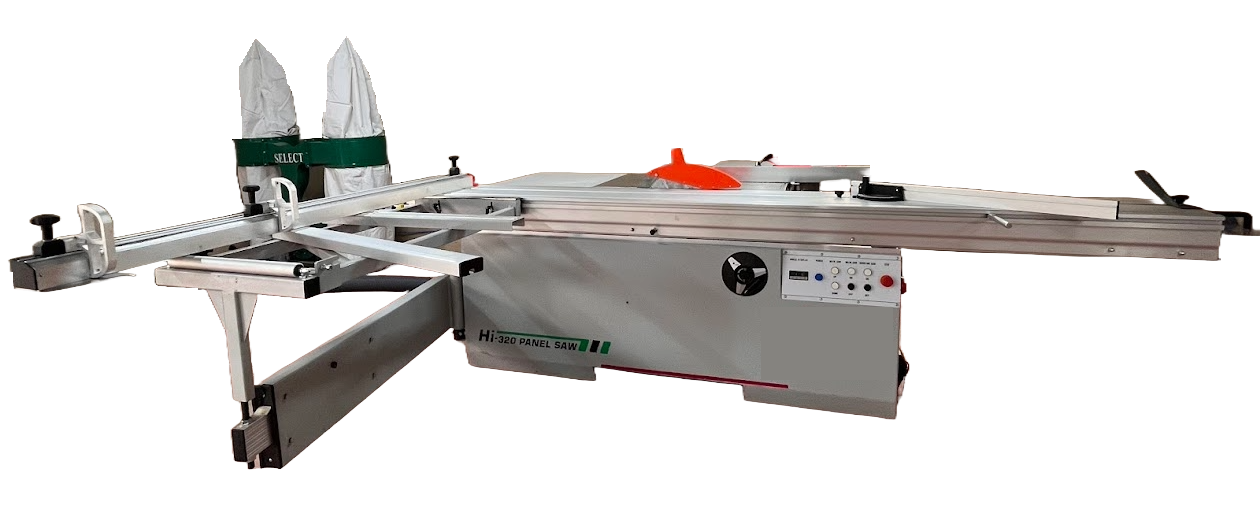

Redefining Plywood cutting

Our Hi-tech panel saw machine aims to redefine the wood-cutting process with high precision, offering unmatched speed and accuracy in cutting panels to exact dimensions. This process reduces material waste & helps optimize material utilization and elevates overall production efficiency.

Advantages of High-tech panel saw

- Unparalleled precision

- Cutting with accurate dimensions

- Minimizes material waste

- Boosts production efficiency

Good-bye to manual lamination & Say-Hi to Bubble-free finish

Say no to manual laminations. Our 50 Tons Cold Press machine is set to revolutionize Plywood pasting by eliminating the inconsistencies and imperfections of manual pasting – which leaves air bubbles & uneven glue distributions. A Cold Press machine is a hydraulic press that applies even pressure to the laminated sheets, ensuring a strong and uniform bond. It protects the wood against stains and smudges, it’s easy to install, easy to clean, is resistant to impact, shock and pressure, and increases durability.

Advantages of 50T Cold Press

- Consistent pressure distribution

- Improved efficiency

- High-quality output

- Air bubble-free laminations

- Reduced labor costs.

“Precision engineered for perfection. Plywood automation machines are transforming the way we build Interiors”